Validation & documentation packages: Enflex's modular offering

In the pharmaceutical industry, adhering to regulations is a crucial and complex task, involving both the production environment and machinery documentation. Regulations mandate rigorous standards and manufacturing practices (GMP - Good Manufacturing Practices) with detailed specifications to ensure the quality and safety of pharmaceutical products. In this context, Enflex stands out for the qualified support it provides to its clients through a specialized team dedicated to validation documentation and equipment qualification for GMP environments.

From Basic to Elite: Enflex’s complete range of documentation & validation packages

Enflex has designed a suite of modular documentation and validation packages, crafted to perfectly fit any validation need.

It starts with the Basic plan, which ensures that equipment is installed correctly and operates effectively through Installation Qualification (IQ) and Operational Qualification (OQ).

The Plus package extends the Basic by including the Pharma Factory Acceptance Test (FAT) and the Site Acceptance Test (SAT) for even more thorough verification. A more sophisticated offering is the Premium package, which integrates a detailed Qualification Plan and Risk Analysis, covering all tests from the previous packages and providing a comprehensive risk analysis. The Elite plan is Enflex's most complete offering, featuring functional design specifications for hardware and software, along with Design Qualification (DQ), ensuring total coverage from design phases to operation.

The Importance of Qualification Protocols in the Pharmaceutical Sector

In the pharmaceutical sector, Risk Analysis (RA) is crucial for ensuring the safety and effectiveness of products. Among the most advanced techniques stands the Failure Mode and Effects Analysis (FMEA), an analytical process that examines each component of the equipment to anticipate and mitigate potential failures, assessing their implications, frequency of occurrence, and ease of detection.

The design of each piece of equipment begins with drafting the Functional and Design Specifications (FDS). This document is divided into Functional Specifications (FS), which outline the functional scope of the project, and Design Specifications (DS), detailing every aspect of the mechanical, electrical, and programming design.

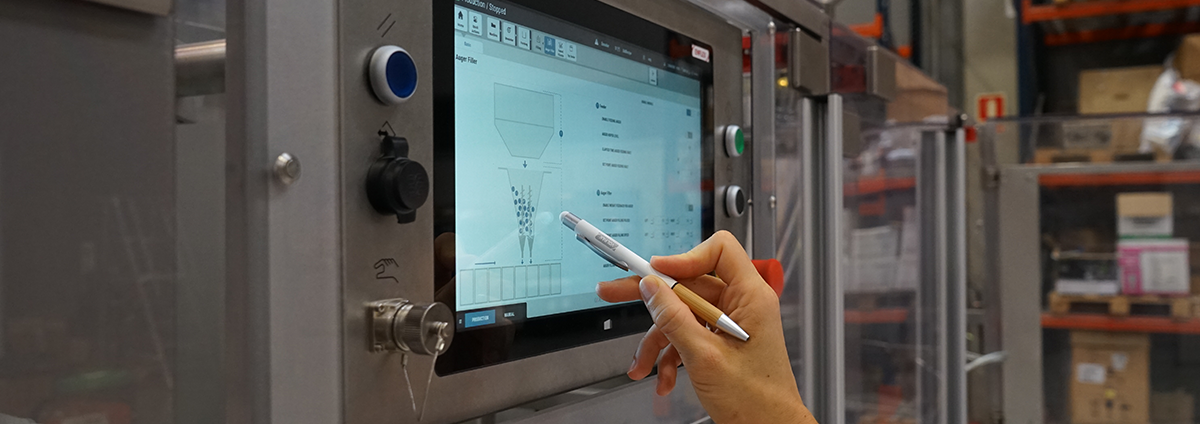

For an even more detailed approach, the HDS (Hardware Design Specifications) and SDS (Software Design Specifications) come into play, expanding the FDS by precisely outlining the automation system design. These documents include critical elements such as system architecture, user interface, PLCs, sensors, and safety devices, ensuring that hardware and software meet rigorous operational and safety requirements.

The journey towards design excellence continues with the Design Qualification Protocol (DQ), which ensures that every detail of the design reflects the defined requirements. The DQ forms the foundation for the start of equipment construction, confirming its adherence to customer needs and expectations.

The verification phases of the equipment are realized through Factory Acceptance Test (FAT) and Site Acceptance Test (SAT) protocols. These tests, essential before delivery to the customer and following installation, examine every aspect of the equipment, from documentation to functionality, ensuring that each component functions perfectly as expected.

Finally, the Installation Qualification (IQ) and Operational Qualification (OQ) protocols represent crucial steps for validating the installation and operation of the equipment. While IQ confirms that the installation meets the technical specifications, OQ tests the functionality of the equipment, ensuring it operates flawlessly according to customer requirements.

Enflex: a reliable and innovative partner

In an industry where safety and efficiency are not just required but essential, Enflex emerges as a beacon of reliability and innovation. Through close collaboration with customers, Enflex customizes each protocol, ensuring that systems are not only impeccably installed and operational, but also precise in meeting market needs. Thanks to Enflex, the path to regulatory compliance not only raises safety and efficiency standards, but also reaffirms its commitment to innovation and excellence in the pharmaceutical sector.