Precision Packaging: Advanced Technologies to Safeguard Pharmaceutical Powders

Understanding the complexity and diversity of pharmaceutical powders is essential in the Pharma & Healthcare industry. These substances are not just foundational to drug delivery; their effective packaging is crucial to ensure potency, safety, and usability. As pharmaceuticals evolve, so does the technological precision behind packaging these delicate materials.

Understanding Pharmaceutical Powders

Pharmaceutical powders comprise a wide range of finely divided, particulate substances designed for medicinal use. Common forms include powders for tablets, capsules, and direct consumption, each serving specific therapeutic functions. Indeed, these powders vary in composition, characteristics, and uses – all of which significantly influence their packaging needs.

Powders can be initially classified based on their use. First, bulk powders are used in large amounts for various applications. Dusting powders, containing medicinal agents and bases like talc, are used on the skin to prevent irritation. Powder sprays, which require particles under 50 microns, provide a uniform distribution for topical use. Douche powders are, instead, formulated for intimate hygiene and are usually packaged in metal foil to maintain freshness. Insufflations are fine particles for inhalation via an insufflator. Divided powders are single-dose medications that ensure dose accuracy and protect from environmental exposure. Lastly, efflorescent powders, containing crystallized substances, can release water and become sticky in low humidity, thus needing careful handling.

Even more relevant when determining the most appropriate packaging for powders is a differentiation on the basis of their physical properties. Particle size, for instance, affects a powder’s density, flowability, and solubility, impacting everything from storage to transport. Bulk density, instead, measures the density of a granule or powder, highlighting the amount of space occupied by air, which influences equipment sizing and transportation costs. Flowability is crucial for handling operations, and poor flow can lead to equipment damage due to lump formation. Hygroscopicity, or a powder’s tendency to absorb moisture, can further complicate flow and storage, necessitating specific moisture control measures.

Solubility affects how a powder interacts with liquids, crucial for industrial processes involving liquid incorporation, whereas wettability determines how quickly a powder integrates with water, impacting its utility in instant mix applications. Finally, dispersibility, the ease with which a powder dissolves in water, is vital for ensuring uniformity in products like instant drinks or infant nutrition. Each of these properties, together with the nature of the pharmaceutical product and its utility, must be carefully considered to ensure optimal solutions for packaging and handling such diverse materials.

Challenges in Pharmaceutical Powder Packaging

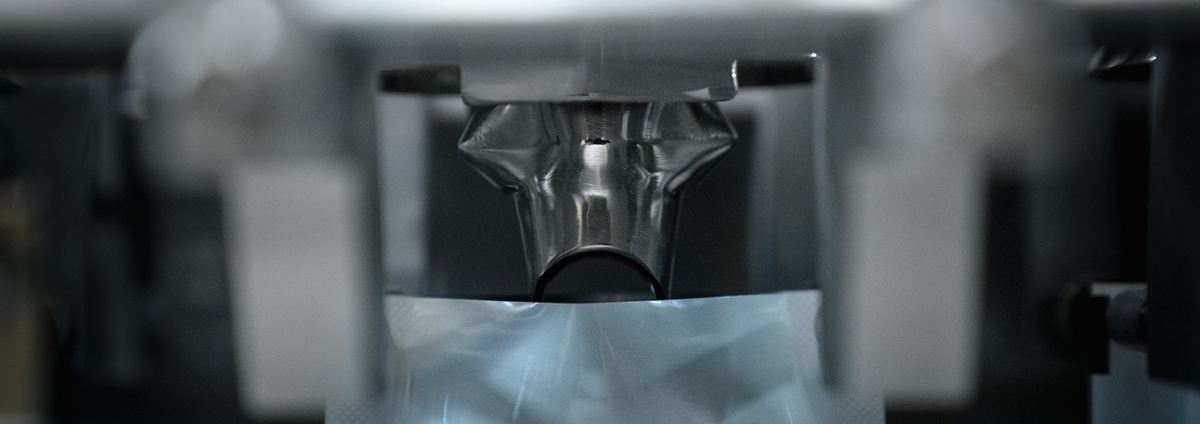

When it comes to packaging pharmaceutical powders, several challenges arise that are crucial to address to maintain the product’s integrity and effectiveness. Moisture absorption, particle segregation, and potential contamination during packaging are just some of the most significant hurdles that can compromise the quality of pharmaceutical products. Recognizing these challenges, Enflex is committed to design and commercialize advanced technologies that prioritize both production safety and flexibility, such as Horizontal Form Fill Seal (HFFS) systems for flat pouches, Stick Pack machines, and Vertical Multilane (VML) systems also for sachets. These packaging technologies ensure that pharmaceutical powders are well-protected from adverse environmental factors. This complies with stringent health regulations. Indeed, as previously mentioned, choosing the best packaging solution involves first and foremost evaluating the specific needs of the powder’s properties and the physical conditions of the packaging process, areas in which Enflex excels by providing tailored solutions that meet these complex requirements.

Enflex’s Commitment to Excellence in Pharmaceutical Packaging Innovation

Enflex has established itself as an expert in the dosing and packaging of pharmaceutical powders among others. Our advanced packaging solutions for pharma ensure that each pouch is crafted to provide the utmost protection for its contents, guarding against contamination, moisture, and other environmental factors. This attention to detail and commitment to quality not only preserves the efficacy of the pharmaceutical products but also guarantees consumer safety. Additionally, the efficiency and low operational costs of Enflex’s packaging systems make them an invaluable asset for pharmaceutical companies looking to optimize their production lines.

The future success of the Pharma & Healthcare industry and the well-being of its consumers are intricately linked to the evolution of packaging technologies. We at Enflex play a crucial role in this sector by applying our deep understanding of pharmaceutical powders' behavior and the unique challenges they present. With an unwavering commitment to innovation, Enflex designs packaging solutions that directly address these challenges through tailored, advanced technologies present in all our machine systems. In Pharma & Healthcare, the end goal is protecting customers: we do so by protecting medications. By continuously advancing its packaging technologies, Enflex continuously sets new standards in the packaging domain, guaranteeing that pharmaceutical powders are delivered safely, effectively, and with the highest degree of quality.

Discover how Enflex’s cutting-edge packaging solutions can transform your pharmaceutical products on our Pharma & Health dedicated webpage.

DATA SOURCES